Hello and welcome guys today in this post I will tell you Mosfet blast Welding machine repairing technique. If you get any damage to your ARC welding machine after a blast inside, this post will help you to repair your MOSFET blast dead welding machine.

Actually, when we did welding in any place, at that time if anything goes wrong with the welding machine immediately we get a blast sound inside the welding machine. This problem we get because of heavy load and sort circuit.

When we get blast sound and smoke from inside the welding machine, this means some components getting burned. Most of the time this happens with the MOSFET and IGBT. If you welding machine designed with MOSFET, you get MOSFET burned. And if your welding machine is designed with the IGBT, you will get IGBT Burned. To fix your problem follow the below instructions.

MOSFET Blast Welding Machine Repairing Technique

Table of Contents

- First check the Burned components inside your welding machine.

- After find the burned component remove them from the PCB.

- Now you have to understand what kind of components have burned. I already mention in the above, most of the time we get burned MOSFET or IGBT. But in your case it may be different.

- If your welding machine have MOSFET or IGBT, just find the number. You will get data of you burned components from the internet. just download the datasheet from the internet accordint to the component part number.

- After that fine the same number component and install in the same place.

- If you did not find the same number MOSFET or IGBT you can install higher value same component. For Example in your welding machine have 40N60 MOSFET and you did not get same number from the market, that in this place you can install 45N60, 46N60, 48N60, etc like this. This is the actual technique of MOSFET Blast Welding Machine Repairing.

NOTE: In my whole life experience I get MOSFET and IGBT blast from this type of welding machine problem. So you can follow the above process and repair your welding machine problem.

If you have any kind of queries and questions regarding the MOSFET Blast Welding Machine Repairing Technique with Equivalent Mosfet in your mind, you can drop your thinking in the below comment box. I will reply to you within 2 or 3 days.

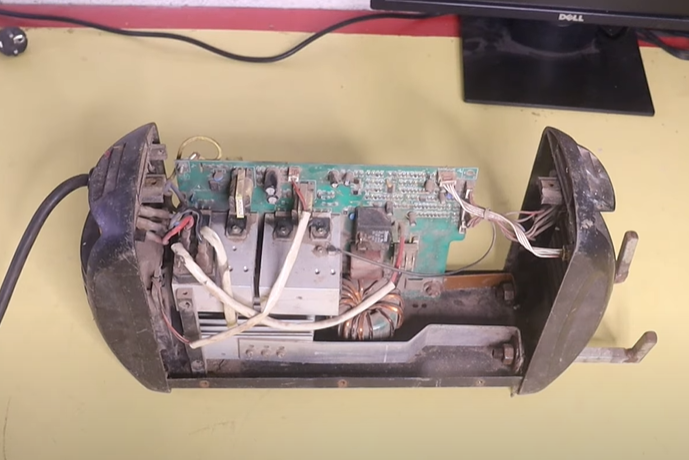

Some Pictures of Burned ARC Welding Machine Repairing

Watch Video of Blast and Dead DC Welding Machine Repairing Full Guide

Others Electronics Gadgets Repairing Technique Link

- LCD LED Repairing Guide Ebok In Hindi

- Morpho device Repairing Technique

- Electric Cooket repairing technique

- TDA2030 home Theater Kit Wiring Diagram Full details

- LCD LED TV Repairing technique

- CRT TV Repairing technique

- Electronics Repairing Practical Video

FAQ of How to Repair Dead Welding Machine

How do you troubleshoot a welding machine?

It is very easy to repair a welding machine. just follow the rules of the electronic welding machine repairing technique. I have explained this in this article MOSFET Blast Welding Machine Repairing Technique with Equivalent Mosfet.

Why did my welder stop working?

If anything getting damage inside a welding machine, your wedding machine will stop working. to fix this problem you have to apply the welding machine repairing technique, which I explain in this article. you can read this article to know the welding machine repairing technique.

Arc welding machine problems and solutions

we get lots of problems inside an Arc welding machine. I have explained how to repair burned MOSFET in arc welding machine in this post. If you get anything burned inside your arc welding machine you can apply this technique to repair your arc welding machine.